| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Brand Name : BaseTi

Model Number : THB012

Certification : ISO9001:2015

Place of Origin : China

MOQ : NO MOQ LIMITATION.

Price : CONTACT US

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 10,000 tons/month

Delivery Time : 12~20 days

Packaging Details : External: wooden box packaging; Inside: an inner packing with protective foam;

Grade : Ti-6Al-4V, Ti-6Al-7Nb, Ti-3Al-2.5V, Grade 5, Grade 9

Hardness : Varies depending on grade

Heat treatment options : Annealing, Normalizing

Melting Point : Typically around 1,660°C (3,020°F)

Density : 4.43–4.51 g/cm^3

Production standards : ASTM B265, ASME SB-265, ISO 5832

Tolerance : Thickness: +/- 0.1mm; Width: +/- 0.5mm; Length: +/- 1.0mm

Rolling process : Hot rolling, Cold rolling

Surface process : Polished, Sandblasted, Pickled

Size : Thickness: 5-200mm; Width: 500-3000mm; Length: 1000-12000mm

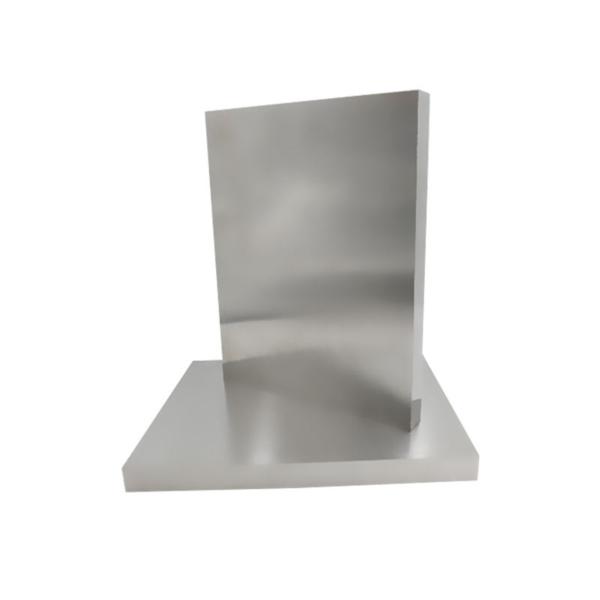

Alloy Titanium Plate Sheet Manufacturer Source Factory For Industry ASTM B265, ASME SB-265 Grade 5, Grade 9

*If you have any requirements for customized titanium plate, we would be delighted to further discuss the technical specifications with you and provide a quotation.

*Our production capacity is efficient, and our logistics channels are well-developed. We can deliver products via international express to any corner of the globe within 3 to 7 days.

Titanium plate specifications & parameters | |

| Product name | Titanium plate sheet |

| Application field | Aerospace, Automotive, Shipbuilding, Defense, Structural Engineering |

| Available size | Thickness: 5-200mm; Width: 500-3000mm; Length: 1000-12000mm |

| Grade | Ti-6Al-4V, Ti-6Al-7Nb, Ti-3Al-2.5V, Grade 5, Grade 9 |

| Production stadards | ASTM B265, ASME SB-265, ISO 5832 |

| Tolerance | Thickness: +/- 0.1mm; Width: +/- 0.5mm; Length: +/- 1.0mm Hot rolling, Cold rolling |

| Rolling process | Hot rolling, cold rolling |

| Surface process | Polished, Sandblasted, Pickled |

| Delivery time | 15-20days |

| Key words |

|

Welcome to the world of Alloy Titanium Plates, a technological marvel in the field of advanced materials. With characteristics ranging from high tensile strength to corrosion resistance, these plates are gaining unprecedented attention across various sectors. Notably, BaseTi is a leading manufacturer setting industry standards.

Industry Data:

Alloy Titanium Plates are indispensable in aerospace for their high strength-to-weight ratio. From the fuselage to landing gear, these plates are engineered to withstand high-stress environments.

Industry Data:

BaseTi Alloy Titanium Plates are increasingly sought-after for their potential to reduce vehicle weight while enhancing performance.

Industry Data:

In marine engineering, Alloy Titanium Plates offer unparalleled corrosion resistance, making them the go-to solution for components like ship hulls and propellers.

Product Data:

BaseTi is the manufacturer of choice for medical-grade Alloy Titanium Plates. They are used in surgical instruments, bone plates, and dental implants.

Product Data:

In various industrial settings, these plates are used in heat exchangers, cooling towers, and chemical reactors.

Alloy Titanium Plates are revolutionizing multiple industries, offering tailor-made solutions for a range of applications. As a leading manufacturer, BaseTi provides products that are a testament to technological advancements.

| Grade | ASTM Standard | Tensile Strength (psi) | Yield Strength (psi) | Elongation (%) | Hardness (HV) | Thermal Conductivity (W/mK) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|

| Ti6Al4V (Grade 5) | ASTM B265, ISO 5832 | 130,000 – 150,000 | 120,000 | 10 - 15 | 330-370 | 6.7 | 4.43 |

| Ti3Al2.5V (Grade 9) | ASTM B265, ISO 5832 | 90,000 – 120,000 | 70,000 | 15 - 20 | 300-340 | 7.2 | 4.48 |

| Commercially Pure (Gr 2) | ASTM B265, ISO 5832 | 50,000 – 80,000 | 40,000 | 20 - 25 | 150-220 | 21.9 | 4.51 |

This tabulation incorporates several crucial parameters including tensile strength, yield strength, elongation, hardness, thermal conductivity, and density, providing a 360-degree view of the material properties under various grades and standards such as ASTM B265 and ISO 5832. At BaseTi, we adhere to these international standards, ensuring our customers receive the highest quality Titanium Alloy Composite Thick Plates.

|

|

Grade 5 Grade 9 Titanium Plate Sheet Medical Titanium Sheet For Industry Cold Rolling Images |